1. First thing is to remove the large compression C clip that holds the compressor housing on.

2. Second is to remove the 4 bolts that hold on two C shaped brackets to the exhaust housing. Once removed heat may need to be applied to help break it loose from the center cartridge. Pay special attention when removing it as it does not get caught up on the turbine blades, best way to do this is to keep spinning the shaft while wiggling it loose.

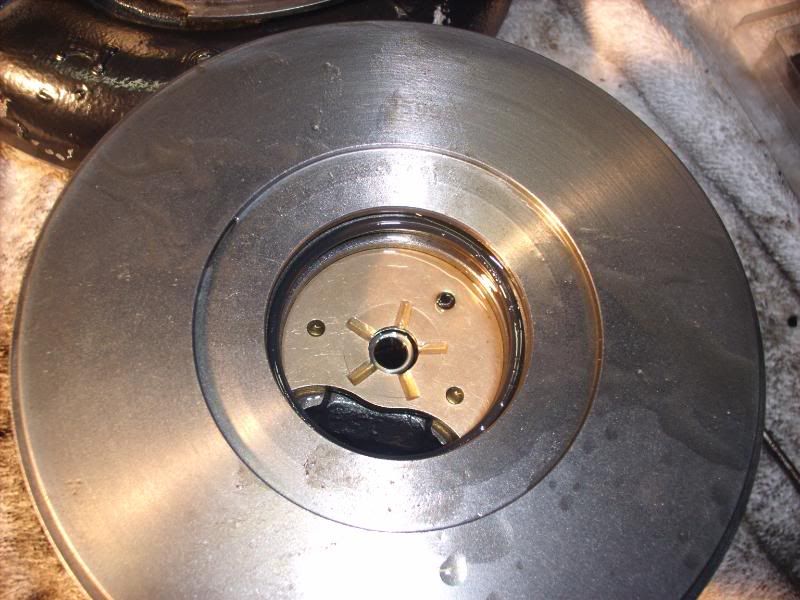

3. Next you are left with the center cartridge with wheels and shafts intact. You want to make a mark on the wheel and the shaft, both with a paint pen and a scribe to etch a small mark so it can later be lined up for assembly.

4. Then use a 12pt open ended wrench to remove the nut from the compressor wheel keep in mind it is left handed threads.

5. Once the compressor wheel is off you will see a another C clip, remove that

6. Once C clip Is off you will now see the seal plate/deflector, that will come right out

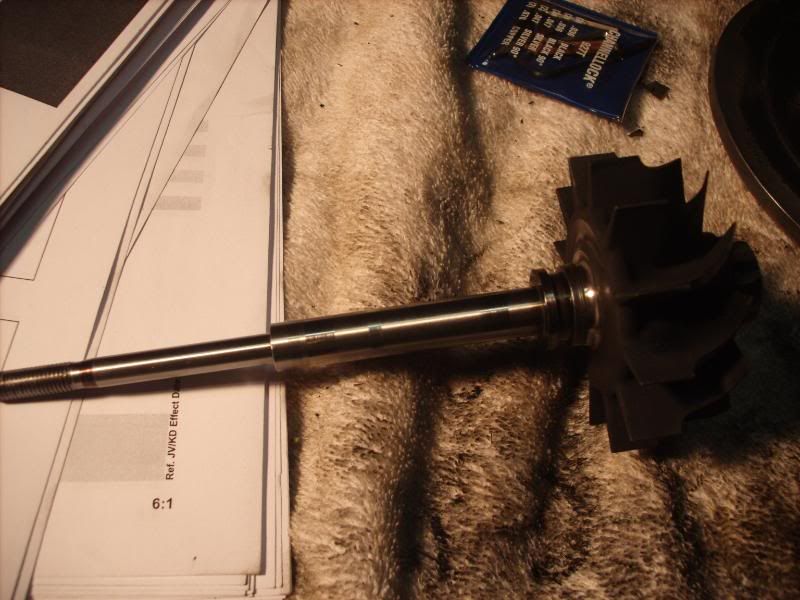

7. Once the seal plate is off you will see the oil deflector then the thrust bearing that just comes right out, there is also a piston ring which holds the shaft in place, remove that and the shaft will then slide out of the housing. A heat shield will also come off which just rests in place right before the turbine blade.

8. After the thrust bearing is removed you will see this (not sure on the name) some collar maybe which also comes right out.

9. Sequence of parts thus far:

10. Now you will start to see the journal bearings, the first one which is held into place with a very small C clip, remove the clip and the first journal bearing comes right out.

Fuel/Air: 475cc P-Pump, 5x.014's, Airdog 150, BW 66/68/14

|

11. Right after the first journal bearing comes you will then see a

second C clip further down in the housing, remove that and then flip the

cartridge over to the turbine side and remove the last C clip.

12. Sequence of parts this far:  13. Now you have an empty cartridge and you can then begin my reassembling it all, but before spray it down real well with some brake cleaner to get it nice and clean.  14. Then start by adding the first small C clip in the turbine end(deep in the cartridge) then using oil install new journal bearing and then reinstall the other C clip, do the same on the compressor side. You can then add the piston rings to the turbine end of the shaft.    15. Once journal bearings are in start to reinstall all the other components, collar, thrust bearing, oil deflector, piston ring, seal, seal plate, larger C clip. All the while this is going on you need to stick the shaft in awhile.         16. Up to this point it was just reversing install, then you’ll put on the compressor wheel and line up the markings while tightening, I’m no expert on this I just did it and took pictures, it was a little bit of a challenge, but a good learning experience. I hope you all can sort of get a jist of how its done. I didn’t take any more pictures after this point but once the compressor wheel is on and tight, its just a matter of putting on the housings and your ready to roll. Here it is mounted back on the truck with a 14cm housing in its place of the 12. I hope you guys enjoy this.  Fuel/Air: 475cc P-Pump, 5x.014's, Airdog 150, BW 66/68/14 |